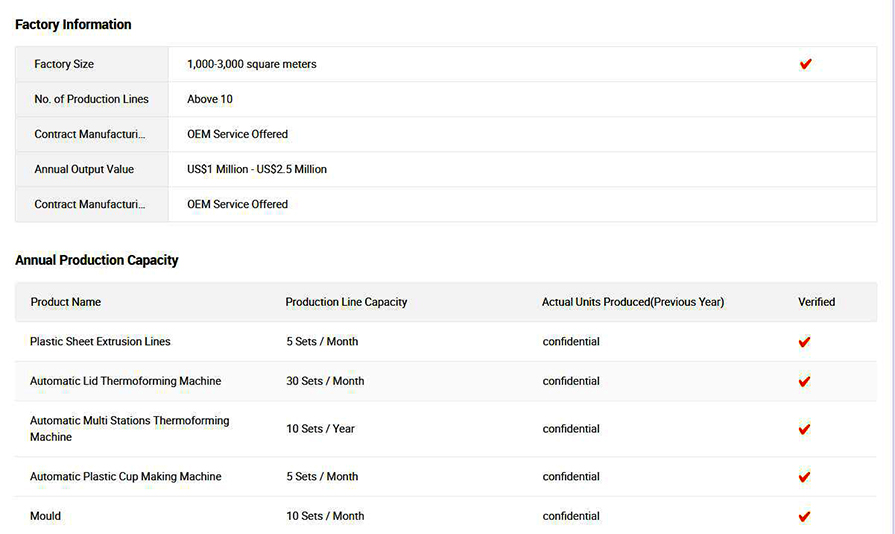

Main Technical Parameter

|

Model |

SPC-680 |

|

Forming Area |

Max. 680x420mm |

|

Mould Area |

720*520mm |

|

Depth of Draw Under Sheet |

Max. 60 mm |

|

Depth of Draw Above Sheet |

Max. 70mm |

|

Suitable Material |

PET PS PVC PP |

|

Sheet Width |

460- 760 mm |

|

Material Thickness Range |

0.3-1.5mm |

|

Material Roll Diameter |

Max. 1000 |

|

Dry Run Speed |

Max. 15-25 cycles/min |

|

Power Supply |

3-N AC380V±15V |

|

Power Consumption |

Approx.35kilowatts/hr |

|

Air Pressure |

0.7Mpa |

|

Air Consumption |

2500 Liters/min |

|

Cooling Water Consumption |

13 Liters/min 15° - 20°C |

|

Dimensions |

7.5m*2.0m*2.6(L*W*H) |

Advantage

it is a post-trim type machine which can performance forming, cutting , hole punching, stacking and counting in 4 separate stations by taking advantage of cam system and servo system .

Design Feature

Full Electrical Drive minimizes power consumption and make operation easier.

Cam-controlled drive technology ensures 100% precise repetition of each cycle of forming and cutting.

Cam-controlled Cutting station with simple servo system.

Cam-controlled Forming station with simple servo system.

Cam-controlled Punching station with simple servo system.

Precise index accuracy utilizing Servo drive system, minimizing plastic scrap.

Positive forming and Negative forming(air pressure forming plus vacuum forming.

Up-Stacking system.

Accessing to all digitized functions by pressing touch screen.

Touch screen and programmable PLC control.

PID temperature control ensures precise temperature accuracy.

Automatic lubrication and center oiling.

Little maintenance effort required and long intervals between maintenance.

Most of Components are from multi-national suppliers assures a reliability and worldwide compatibility.

Lateral quick changing tools (moulds) from one side of machine.

Use of Steel rule knife minimizes cost.

1-2 days for line knife making,minimizing cost of operation.

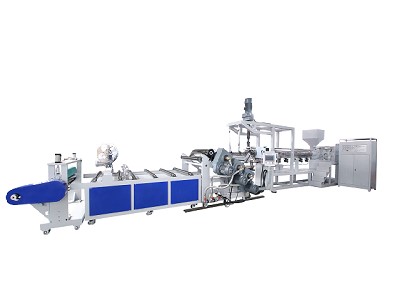

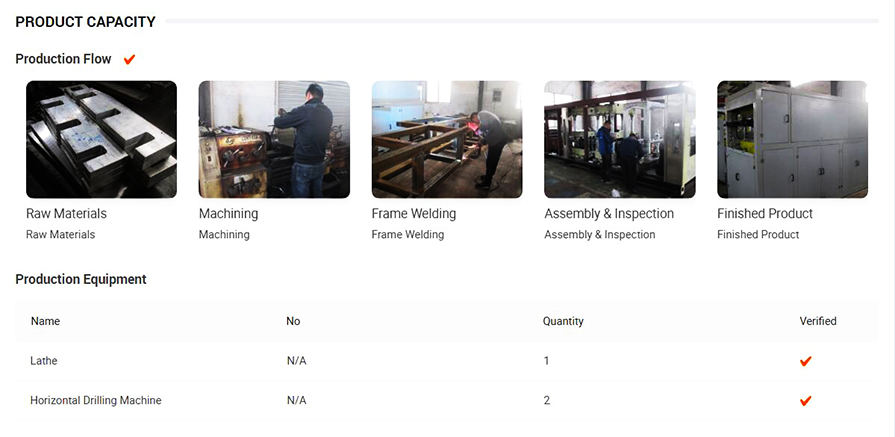

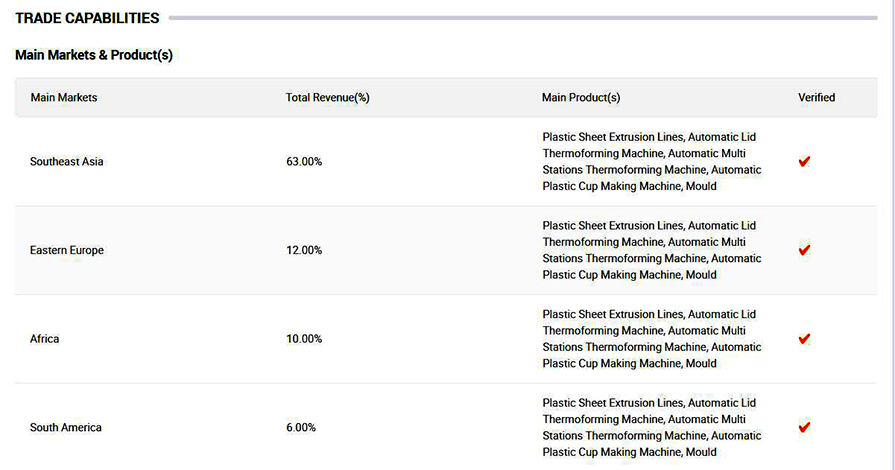

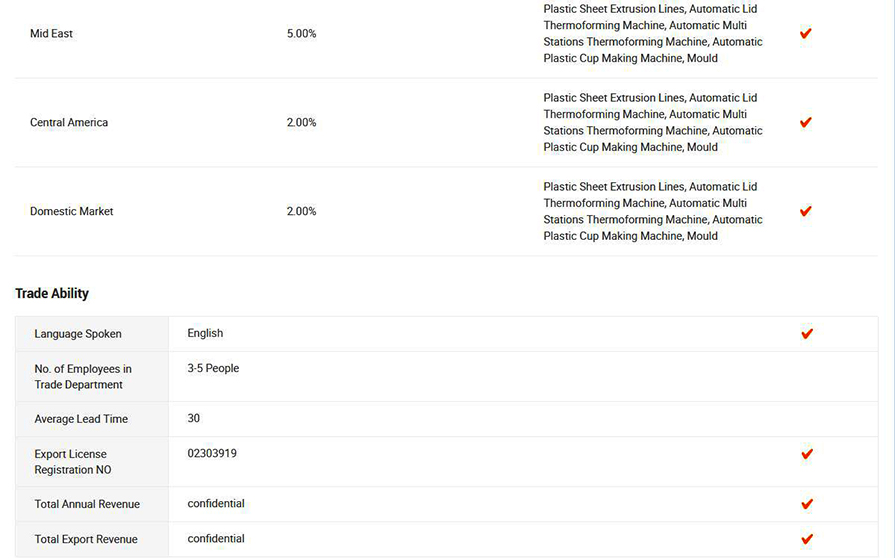

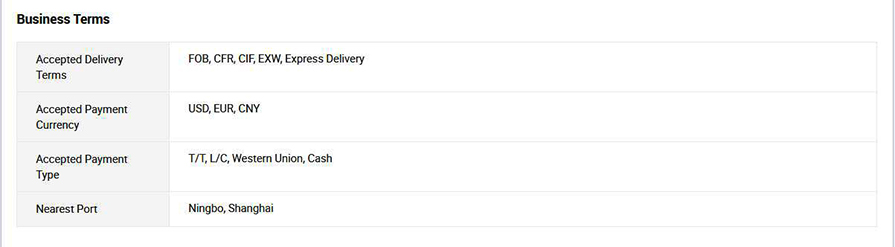

Company Profile

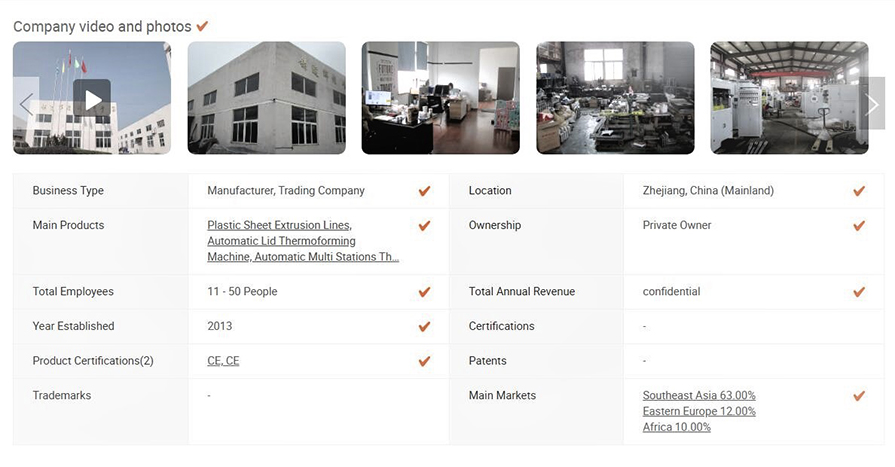

FAQ