Longer Lifetimes

Highest Cycle Speeds

Less Energy Consumption

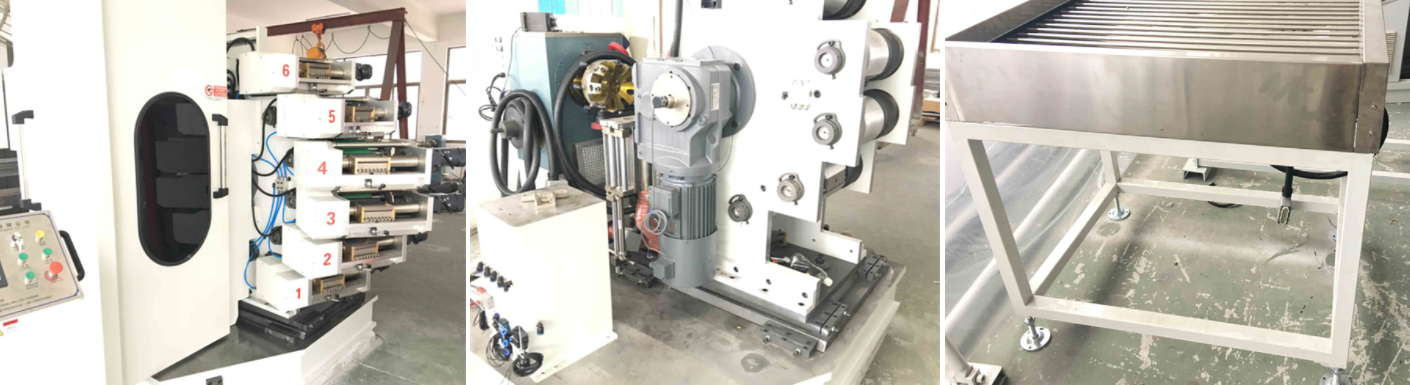

Forming Station

Ease of Use

Increased Availability

Application area:

The equipment is widely used for printing yoghurt cup,ice-cream cup,fast-food bowl,Coca Cola cup and other cylindrical form or circular cone plastic products etc. It with automatic feeding cups, printing, quality inspection,counting function etc.

Main Function:

Automatic Incline type feeder, very easy to operate amd suit for many kinds of cups.

Cup driver can be adjusted easily and operate fluently.

Printing cylinder separates automatic when there is no cup or double cups

The roll gearbox can be automatic adjust the distance, ensure it is no shadow of cup surface.

The printing plate has specialized punch, which can be aligned accurately, quickly and operated easily.

Replacement of mould core or cup mould is convenient and fast.

Inspect function for problem cup by corona.

Printed articles sampling inspection function when working

Automatic counting by servo motor is more accurate, more easy to collect cup

Can be drive rubber model of transfer printing automatic.

Two motors two inverter to control printing system

Finished Product

Finished Product

Finished Product

|

Model |

SP-6180 |

|

Max Printing Depth |

160mm |

|

Cup depth |

50-180mm |

|

Max cup body slope |

5-15degree |

|

Max. Printing Speed |

400 cups/min |

|

Cup Rim Dia. |

Dia.40--180 mm |

|

Cup body depth |

30-180mm |

|

Main motor total power (two motor ) |

8 kw |

|

Total power |

19 kw |

|

Weight |

About 7 T |

|

Dimension ( L*W*H ) |

6200*2500*2660mm |