Longer Lifetimes

Highest Cycle Speeds

Less Energy Consumption

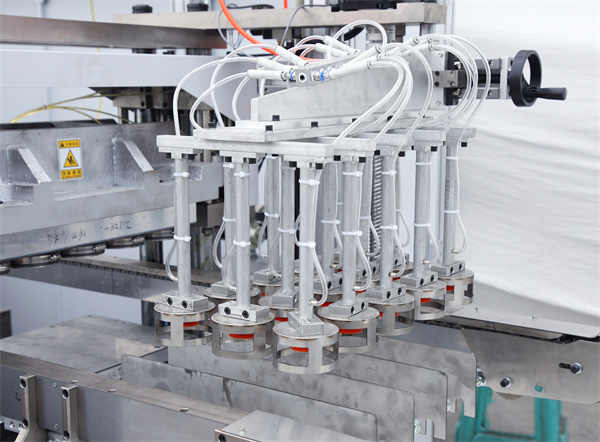

Forming Station

Ease of Use

Increased Availability

Description:

Our special design for PP and PS PVC Film. This machine is suitable for any of thermoforms plastic sheet. This Plastic Thermoforming Machine is update according to the mostly development technical, compare with the traditional machine, It can solved many impossible commitment

This Plastic Thermoforming Machine forming and cutting neat and Clear. Cutting Off the product in order. Also good use for PP PS, PET,PVC etc.

Whole machine is mainly made up by four Parts:

1.Preforming the raw material

2.Forming the products

3.Punching

4.Cutting

5.stacking the products

Finished Product

Finished Product

Finished Product

|

Model No. |

550 |

|

Cutting cycle |

10-40punch/min |

|

Raw Material |

PP/PS/PET/PVC/PLA |

|

Forming area |

550*350*80mm |

|

Heating Power |

TOP heater 43kw, bottom heater 41 kw |

|

Total Power |

380V 50HZ 97KW |

|

Water Consumption |

0.3m³/h (Tap water or recycle water) |

|

Air Pressure |

0.5-0.8(mpa) |

|

Pressure of water supply |

0.2MPa |

|

Dimensions (L×W×H) |

5950*1725*1900mm |

|

Area occupied |

8700*3600 |

|

The maximum diameter of plastic roll |

700mm |

|

Total Weight |

5500KG |