Adopting a vacuum suction structure, each air tube is independently connected to the gas source to ensure that one product is not sucked in and affects other products.

Longer Lifetimes

Highest Cycle Speeds

Less Energy Consumption

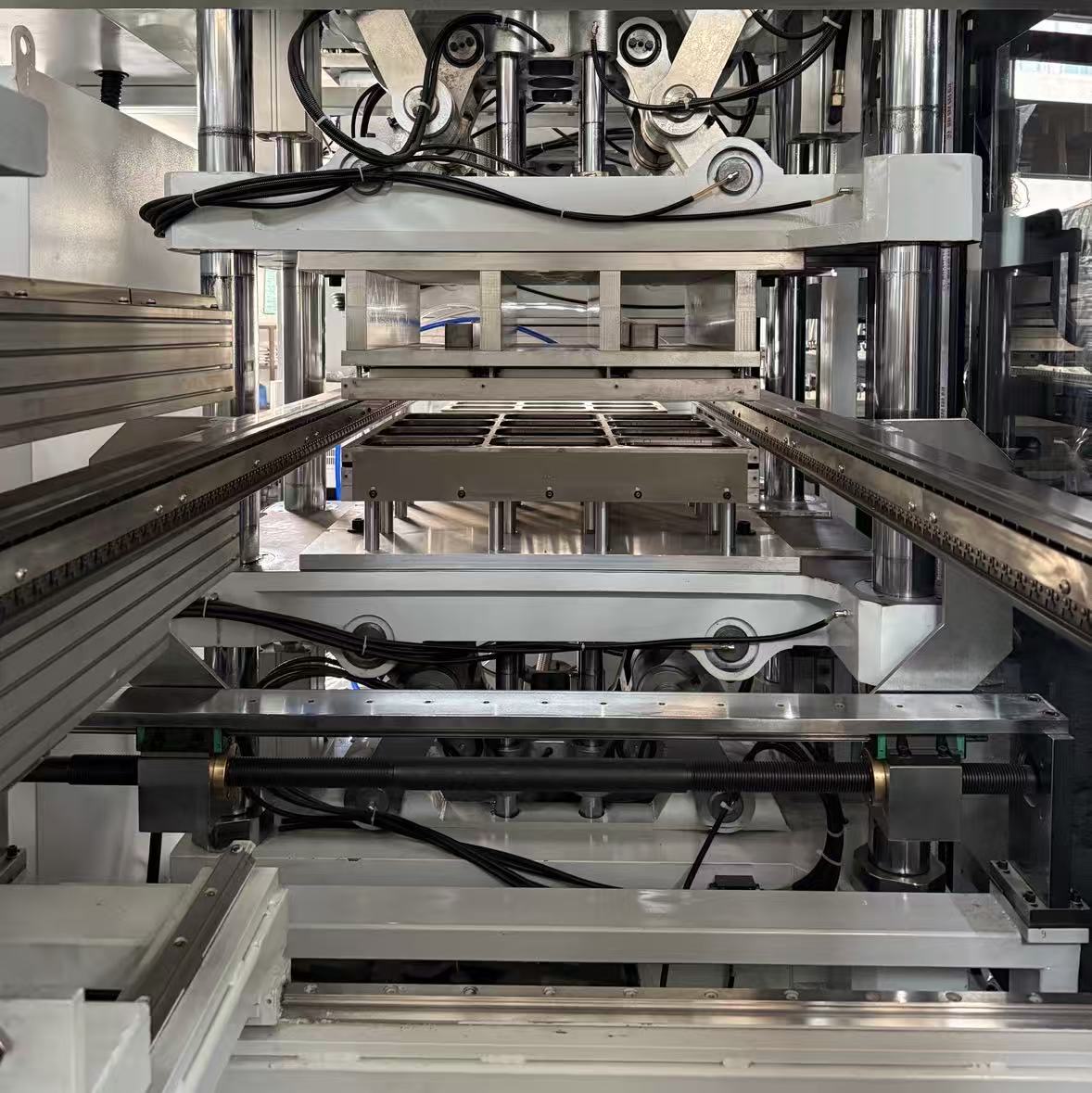

Forming Station

Ease of Use

Increased Availability

High-Performance Thermoforming Technology by Sinoplast

Sinoplast's plastic thermoforming machine is specifically designed for production of disposable lunch boxes, fruit boxes, egg trays and other plastic food packaging products. Equipped with a fully servo-driven system, it has the advantages of high performance, stable forming quality, extremely short mold changing time, high-precision cutting, etc., which help reduce production costs.

Stable Quality And High Specifications

Maximum Forming Layout:780*650MM, Adapt to larger and more complex packaging designs

Cycle Speed:45molds/min,Provide high-speed performance and high-quality products

Maximum Forming Depth: 105MM,When processing products with lower depth, the running speed is faster

This plastic thermoforming machine supports a variety of materials, including PP, PET, PS, and PLA. The maximum sheet thickness can reach up to 2.5MM.

Superior Performance And Energy Efficiency

Operating Power: 50-60KW ,Provides more energy-efficient solutions for long-term operation

Imported Heating Tile: use German ELSTEIN ceramic heating element is equipped with a separate temperature controller for precise setting

Sinoplast’s thermoforming machine can ensure energy efficiency and provide users with more reliable production needs even in high-yield production situations

Precise Control And User Experience

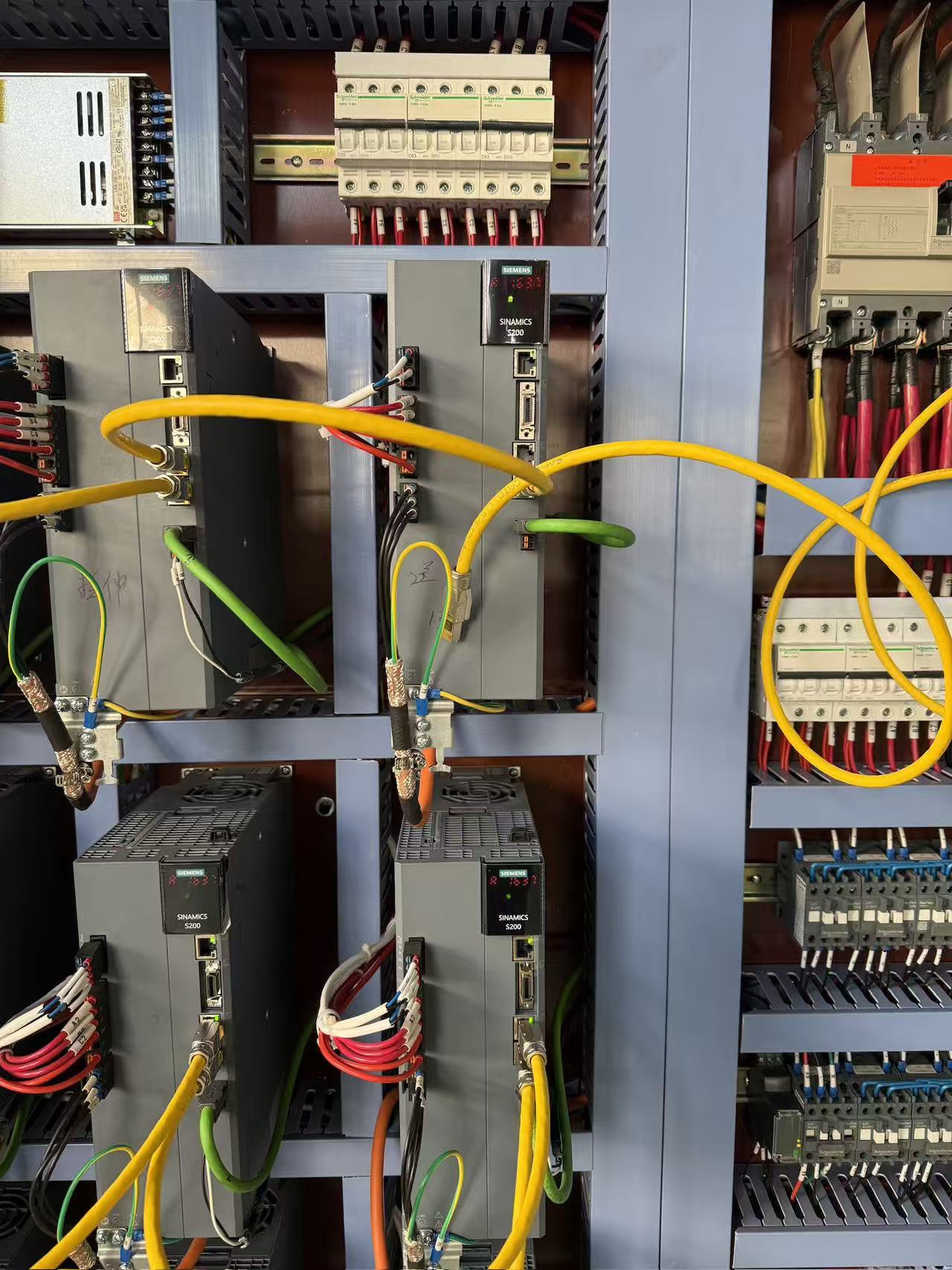

Control System: Equipped with servo motors and PLC control to achieve precise control and automation

Memory Function:Users can store the operating parameters of each set of molds to avoid resetting them due to mold replacement

SINOPLAST:A Reliable Manufacturer Of Thermoforming Machines

SINOPLAST was founded in 2013 and is a globally recognized supplier of thermoforming machines, dedicated to providing sustainable and recyclable plastic packaging solutions.

The company's services include mold design, manufacturing, installation, and commissioning. SINOPLAST is a trusted partner for thermoformed packaging manufacturers, with over a decade of experience representing innovative technology, first-class quality, and excellent service

Lunch Box

Egg Tray

Fruit Box

|

Model |

SPM-780E |

SPM-780D |

SPB-780E |

SPB-780D |

|

Station Number |

3 |

4 |

3 |

4 |

|

Max.Forming Area |

780*540MM |

780*650MM |

||

|

Max.Forming Depth |

105MM(Can be customized) |

|||

|

Suitable Material |

PP/PS/PET |

|||

|

Sheet Width |

550-820MM |

|||

|

Material Thickness Range |

0.15-2MM |

|||

|

Max. Sheet Roll Dia. |

1200MM |

|||

|

Running Speed |

35-40Cycles/min |

|||

|

Forming Station Power |

Servo Motor 7 KW*2 pcs |

|||

|

Forming station stretching |

Servo Motor 3.5 KW |

|||

|

Hole Punching Station Power |

NONE |

Servo Motor 14 KW |

NONE |

Servo Motor 14 KW |

|

Cutting Station Power |

Servo Motor 7 KW*2 pcs |

|||

|

Stacking Station Power |

Servo Motor 3.5 KW |

|||

|

Sheet Feeding Method |

Servo Motor 3.5 KW |

|||

|

Air Consumption/Air Pressure |

3m3/min,0.6-0.8Mpa

|

|||

|

Power Voltage |

380V,50Hz 3P |

|||

|

Approx. Machine Weight |

17T |

21T |

17.5T |

21.5T |