Longer Lifetimes

Highest Cycle Speeds

Less Energy Consumption

Forming Station

Ease of Use

Increased Availability

PET

|

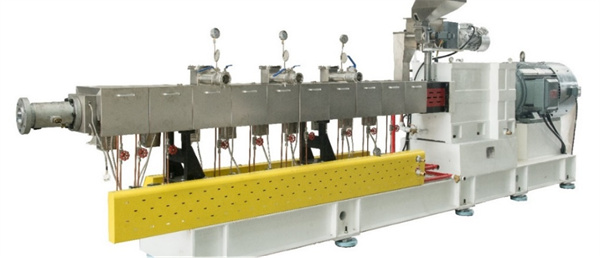

1. SP75 parallel twin screw extruder |

1 set |

|

2. Hydraulic screen changer |

1 units |

|

3. Gear pump |

1 units |

|

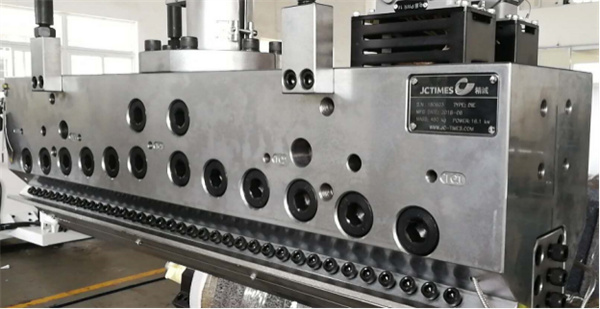

4. T-die |

1 unit |

|

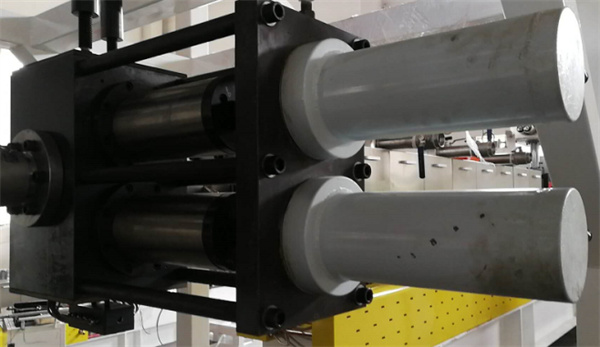

5. Three-roller calender |

1 unit |

|

6. Roller temperature controller |

1 unit |

|

7. Edge trimming unit |

1 set |

|

8. Silicone coating device & Oven dryer |

1 set |

|

9. Haul-off & Anti-static |

1 unit |

|

10. Winder |

1 unit |

|

11. Electric controlling system |

1 set |

|

12. Hot air drying mixer |

1 unit |

|

13. Cooling Chillier |

1 unit |

|

14. Online Crusher |

1 unit |

|

15. Air compressor with air tank |

1 unit |